L&TD

LOGGING & TESTING DIVISION

Surface Logging System & Excell 2000 Application

Time spent at the wellsite is a valuable commodity. How this time is utilized is even more important. If time is not taken to properly analyse and study all available data, decisions that can adversely affect future production of your well or field might be made. Conversely, if too much time is spent at the wellsite, delays in the well program can occur. It all relates back to one thing.

Time spent at the wellsite is a valuable commodity. How this time is utilized is even more important. If time is not taken to properly analyse and study all available data, decisions that can adversely affect future production of your well or field might be made. Conversely, if too much time is spent at the wellsite, delays in the well program can occur. It all relates back to one thing.

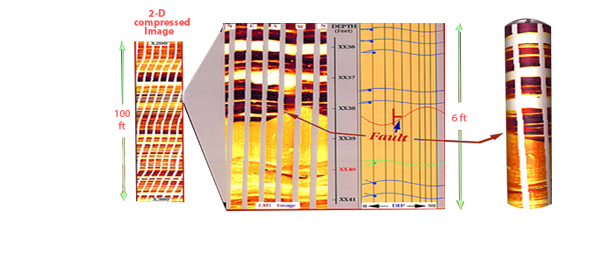

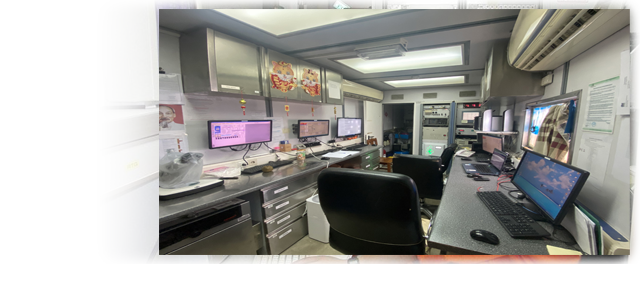

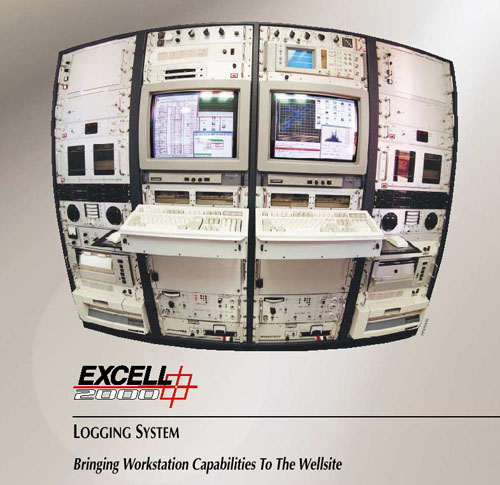

Logging and Testing division realizes the importance of timely and accurate formation data to well program. Excell 2000 TM Logging System is a state-of-the-art integrated logging platform that consistently delivers accurate, high-quality data and provides powerful post-processing workstation capabilities. The system enables greatly improved wellsite performance and provides a standard platform from which new logging tools and software currently in development can be more efficiently operated. And most important, it allows critical formation data to be at the right place, at the right time to help ensure correct decisions are made about your well.

- Faster and More Powerful Capabilities The Excell 2000 unit contains state-of-the-art technology for increased power and speed during data acquisition and processing. This means more tool combinations for specific well conditions and faster logging speeds throughout the job.

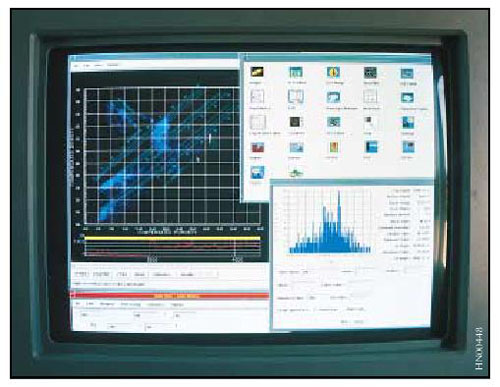

- Multitasking Versatility the powerful processing capabilities of the Excell 2000 System allow multiple applications to run simultaneously. For example, the field engineer can perform post-processing routines, such as SHIVA ™, on acquired data while the tool is still logging.

- Global Data Transmission Excell 2000 is fully compatible with HalSat ™, Halliburton’s new satellite data transmission system. HalSat allows wellsite data to be transmitted to the computing center and computed products to be transmitted back to the wellsite. Data can be transmitted in real time or at the end of logging runs.

- Dual-System Flexibility Fully redun-dant and independent dual-surface systems allow two major functions to be done simultaneously. For example, one system can calibrate a tool string while the other system is logging or processing data.

- Modular Design Individual panels in the Excell 2000 system are modular in design. This flexibility allows each unit to be easily upgradeable to accommodate increases in speed or memory. The Excell 2000 System supports all standard logging, processing, and utility functions within a common environment. This benefits the wellsite logging engineer and saves the client rig time since it is not necessary to change programs for processing, tool function checks and calibrations, or to merge and edit data tapes. Excell 2000 incorporates UNIX-based CLASS software. This proven, time-tested system is currently operating in hundreds of logging units worldwide.

|

|

SYSTEM FEATURES

|

| Desktop Petrophysics is fully integrated into the Excell 2000 System. It allows the operator to manage and manipulate log data for further evaluation and interpretation, utilizing a common desktop

EXCELL 2000 APPLICATIONS

|

|

|

|

| LOGIQ-B SURFACE LOGGING SYSTEM | |

| The LOGIQ-B Logging System is the next generation of Data Acquisition Systems for Halliburton Wireline Logging Services.

For Open Hole Services, the logging software runs under the new platform on a Rack Mount based Windows 2000 environment to provide remote controlled capabilities, real-time petrophysical data acquisition services. The LOGIQ Logging System incorporates the new telemetry and a new power mode scheme while maintaining compatibility for OITS services. For Cased Hole Services, the Cased Hole Software running under Windows 2000 provides real time monocable data acquisition services |

|

The LOGIQ Logging System has three main subsystems:

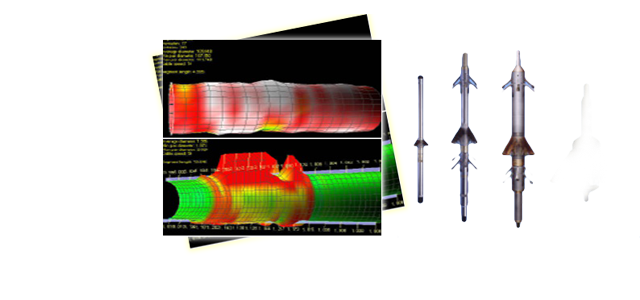

Now you get laboratory precision and rock-solid reliability—no compromise. Gone are the days when you had to choose between precision and reliability. Halliburton’s LOGIQ® platform for openhole wireline logging services is the industry breakthrough that delivers it all. Encompassing advanced downhole logging tools, a higher data rate telemetry system and our powerful PC-based LOGIQ surface system, it also features a dramatic reduction in the length and weight of downhole tools without penalty in temperature or pressure rating specifications. And with that shorter logging tool string comes a much lower potential for sticking. All this with superior service quality. Nhóm Marketing

|

|