L&TD

LOGGING & TESTING DIVISION

Summomer

1. Introductions

SUMMOMER IS A RELIABLE FRIEND OF THE PETROLEUM WELL-BORING COMPANIES

- Summomer is an outguard equipment which applies in well-boring technology effectively. It aims to alert the impact betweent he drill bit and the neighbor drilled wells or the other wells though more long-distance but canpenetrating risk in the depth of adaptation, especially during drilling diagonally

- When drilling in the insert regime, the distance between the wells will be smaller. If the density of drilling wells under the dense terms, risk of drilling bit impact or puncture nearby wells rise considerably. Or during drilling diagonally the collision can cause problems not foreseen, especially for those wells are exploiting with the huge flow

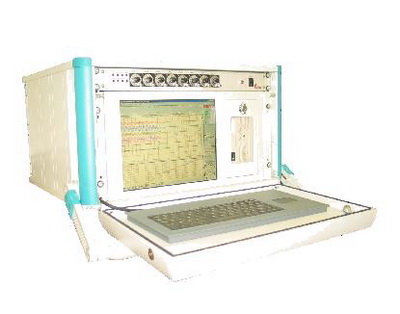

SUMMOMER IS A HIGH-TECH AND COMPACT PRODUCT

- Since the safety of people, the equipment and the whole of the mining it should using the Summomer system to warn about safety during drilling, this equipment is really necessary for the work of drilling petroleum exploitation wells.

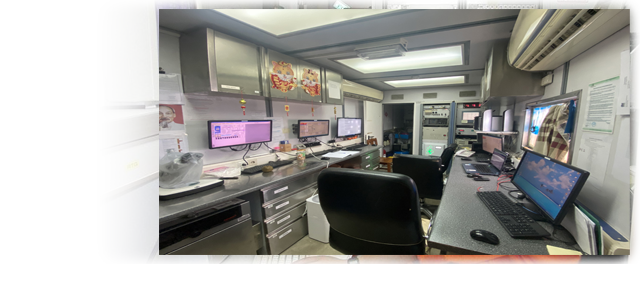

- Outguard apparatus during drilling Summomer is a high-tech and compact product, it designed and manufactured by Vietnamese engineers and IT staff completely. It premise that give systems apply hi-tech to production at Logging and Testing Division - Vietsovpetro in development self-reliant researchs

2. Services

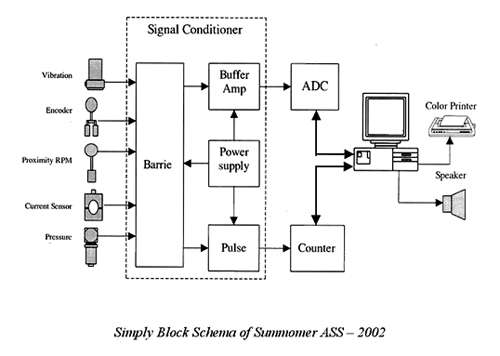

OPERATION PRINCIPLES

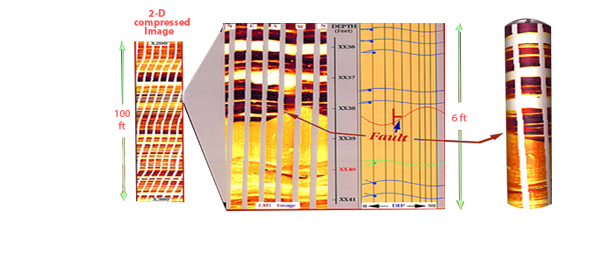

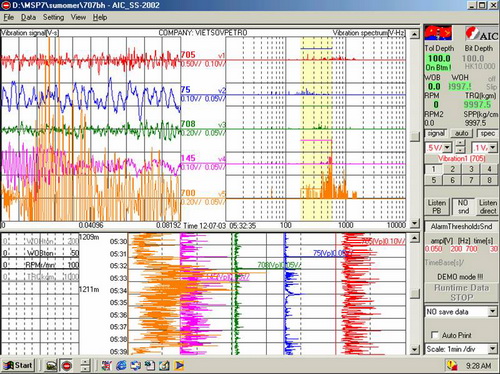

- The vibration sensors are affixed to the casings of the drilling well and the other neighbor wells. The sensors of the drilling parameters are also mounted on the corresponding positions to measure the depth, the speed, the load of suspension hooks and the drilling torsque.

- The computer will acquire the data of all parameters continually. The implementation software analyze the vibration signal spectrum from these casings and combine drilling parameters, so it forecasts the impact capabilities of drilling bit on the nearby wells.

The outguard equipment during drilling Summomer - ASS 2002 has the following functions:

- Continually monitoring the status (approach) of the drilling bit for the neighbor wells during drilling, in order to detect the impact on these wells

- Alarm incident impact. The system will alarm when there is any problem of the impact of drilling bit and early warning capabilities the drill bit approached to some well via increasing in vibration amplitude which acquire from the casing of that well. The alarm or warning is made by whistle, loudspeaker. Also, the information concerning will be message on the screen.

- Store data during the process, analyze the results and shown in the depth or over time as a color chart to facilitate the review of assessment..

APPLICATION EFFICIENCY

Outguard apparatus during drilling Summomer has been used to ensure absolutely safety for the drilling of 30 wells of Vietsovpetro. In fact, the wells virtually alarms risk from a collision or more times and report the impact of the drilling bit to the alongside wells eight times, really help to Wells Drilling and Repair Division processing safety timely. So Vietsovpetro made the task of increasing production and improving the exploitation factor of recovery, ensure safe drilling, does not occur any particularly serious problem for the oil rig, for the people and for the mining

REVIEWS AND EVALUATES

The outguard equipment during drilling Summomer is one of the most successfully achievement of Logging and Testing Division in the work of the application of new technologies into production. That is the result of creative labor of the staff and engineers, who made sense of promoting self-reliant researchs and technology as the main finding stuff on the road design, manufacturing variations own devices of Vietsovpetro to proactively of equipment, people, work for the search of oil and gas exploration and exploitation of Vietsovpetro and service for other petroleum companies more

"Nguyễn Văn Tuyến, Party committee secretary of VietsovPetro "

Summomer is a reliable system. At present thank to apply this system Well Drilling and Repair Division didn’t meet any problem that the drilling bit impacts to exploited wells and drill non interruption to refit Drain-shaft is punctured. So, Vietsovpetro has increased mining production and improve oil recovery coefficient in recent years, secure drill fiability, didn’t occur any particularly serious problem

"Hà Ngọc Khuê, Deputy general manager on Drilling"

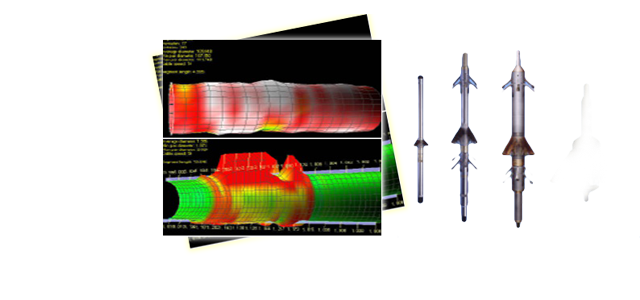

Advanced Securites System (ASS-2010)

Functions:

- Automatic detecting of clash between the drill bit and casing of other neighboring production wells.

- Internal Alarm Management.

- Printer management (Print out Real-time and Playback logs).

- Data management: Backup and store of Real-time database.

Notes: The system uses the spectrum analyses of vibration signals by Fast Fourier Transform Algorithm. While drilling, if any clash between the drill bit and casing occurs then the amplitude of vibration signal is increasing and frequency of signal is concentrated in range of 300Hz - 700Hz, and this phenomenon occurs more chronically to go with drilling parameters changes (e.g. increasing of torque and/or decreasing of rate of penetration,..). This is right indication of the clash.

Nhóm Marketing