L&TD

LOGGING & TESTING DIVISION

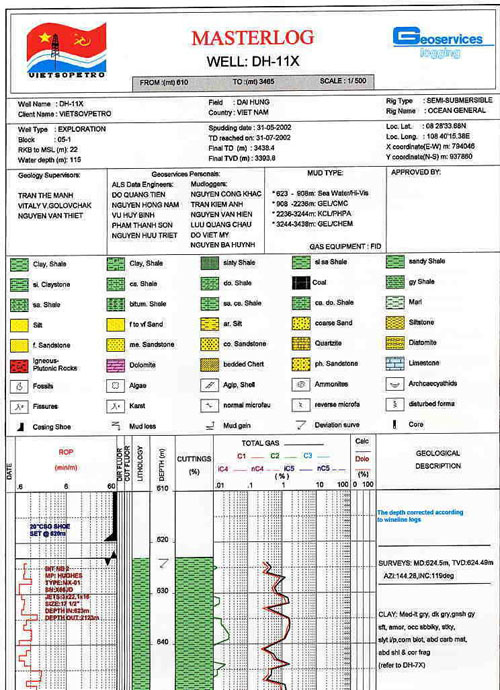

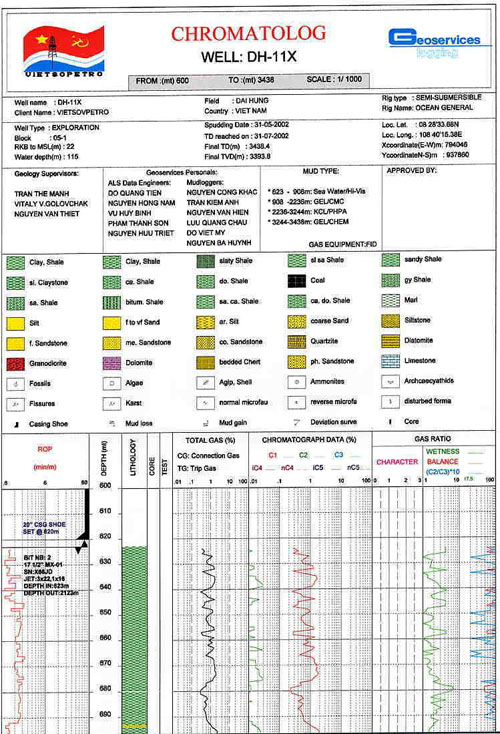

Mud Logging Unit ALS-2

| II. UNIT ALS-2 MUD LOGGING:

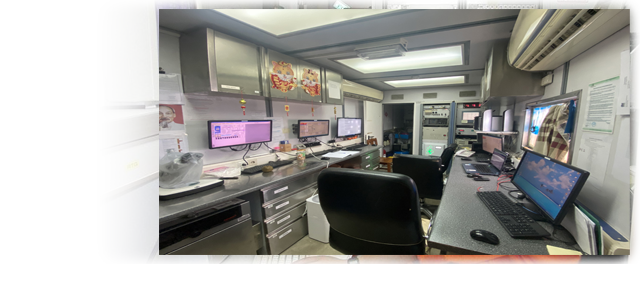

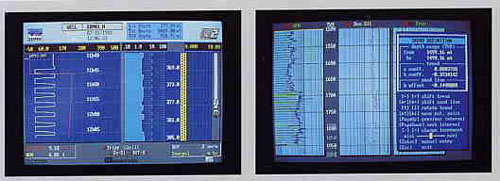

1. Introduction: The ALS-2 Mud Logging Unit provides highly automated monitoring of the entire drilling operation. More than 70 parameters can be measured, processed, displayed, printed and recorded simultaneously. The acquisition system also calibrates the received signals and checks the state of the sensors for electrical faults such as a cut cable or open circuit. In the case of malfunction, an alarm is activated immediately alerting the operator. For data processing a totally new concept has been adopted based entirely on computer technology. The sensor signals are transformed into digital format and then distributed according to requirement. The data is supplied on screen monitors (two types of screen system exist, the “Alpha-numeric” and the “Graphic”) or intelligent interfaces in real-time or playback mode. Alarms can be placed on each parameter. Computerized printouts of desired parameters produce graphic charts of the progress of the well being drilled. In addition the database is continually recorded on magnetic storage support. The ALS is a powerful tool that may be placed in the hands of those with responsibility for the drilling rig. Using many forms of data presentation in the logging unit, monitors or intelligent interfaces can be placed anywhere on the rig. These terminals are “operator friendly” and enable anybody who needs information to have it right there in front of him in real-time or replay mode, and to apply analysis programs if necessary.

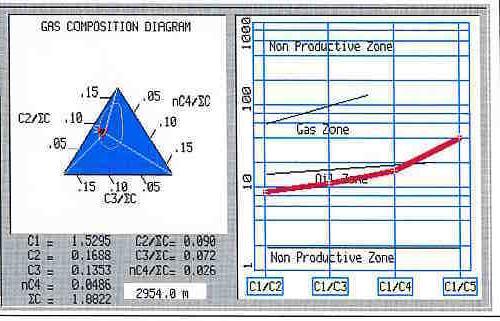

Off-line processing: An offline workstation is part of the ALS-2. This workstation has the following main functions:

- Overpressure - Hydraulics (Bingham, Power Law and other models) - Deviation survey analysis - Surge & Swab - Drilling bit optimization - Bit performance and cost - Kick control - Gas ratio analysis + plots

|

|

|

| 2. Mudlogging equipment and services:

2.1 Mudlogging Unit: Mudllogging unit for offshore operation, complete with:

|

|

2.2 Formation evaluation equipment:

|

|

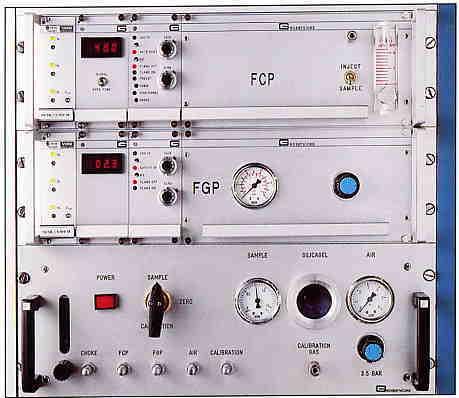

| 2.3 Gas detection system:

The FID (Flame Ionization Detector) Gas Detector & Chromatograph is a well site gas detection and analysis system. It continuously analyses gases extracted from the degasser.

|

|

2.4 Sensors and parameters: Continuous analog recording on colour recorders and digital display on colour monitor of:

|

| 2.5 Computer equipment

Computer equipment consisting:

|

|

|

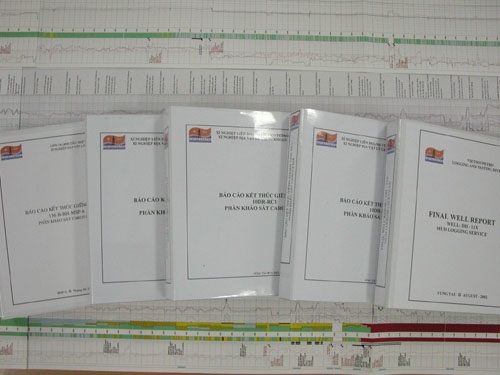

2.6 Reporting:

|

Nhóm Marketing